How many cigarettes are in a pack? Detailed explanation of cigarette box dimensions.

<meta name="description" content="Learn about standard cigarette pack sizes, the reasons why 20 cigarettes is the norm, and how regulations influence packaging design. Explore DHPFactory's custom packaging solutions for your needs."/>Understanding cigarette pack sizes is useful not only for consumers but also for professionals in the packaging industry. Whether you’re designing a new product or sourcing packaging materials, knowing industry norms and regulatory influences can help you make the right decisions. In this guide, we explore standard cigarette pack sizes, why they exist, and how they impact packaging design – DHPFactory can help you create custom solutions tailored to these standards.

Table of Contents

1. Standard Pack Sizes Explained

Across most global markets, a standard cigarette pack contains 20 cigarettes, a size that balances convenience, pricing, and regulatory compliance. Smaller packs, such as 10 cigarettes, are less common and often restricted by local laws. In some regions, you may find larger bulk packs (e.g., 25 or more), typically aimed at different consumer segments.

2. Why 20 Cigarettes Is the Norm

The prevalence of the 20-cigarette pack dates back to early industry standards where manufacturers found it to be the most practical quantity for consumers and distributors. Today, many countries have adopted this size as a legal benchmark to standardize products, reduce confusion, and simplify taxation and compliance.

3. Regulatory Influences on Pack Sizes

Government regulations often dictate minimum pack sizes or require standardized packaging to promote public health goals. For example, certain markets prohibit packs smaller than 20 cigarettes to discourage excessive consumption of smaller, cheaper packs. Compliance with these regulations is a key consideration for packaging manufacturers and brands alike.

4. Packaging Design Considerations

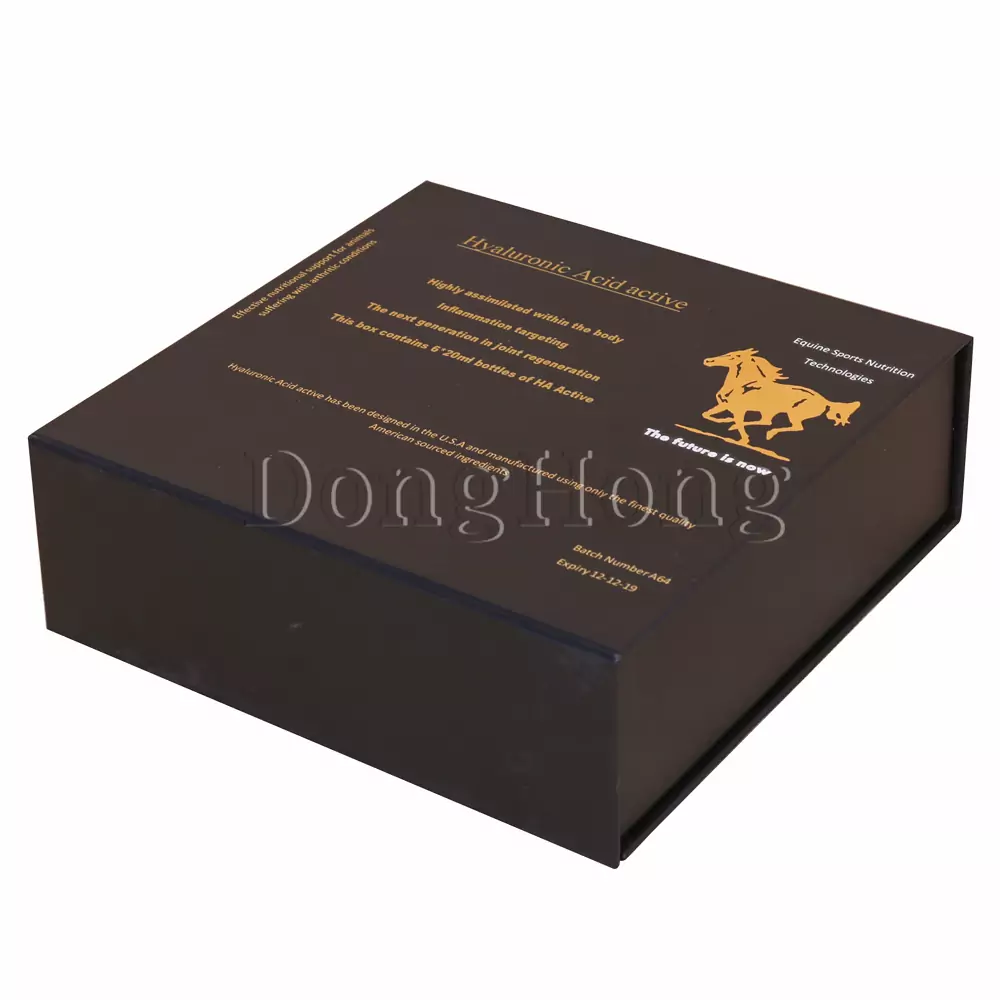

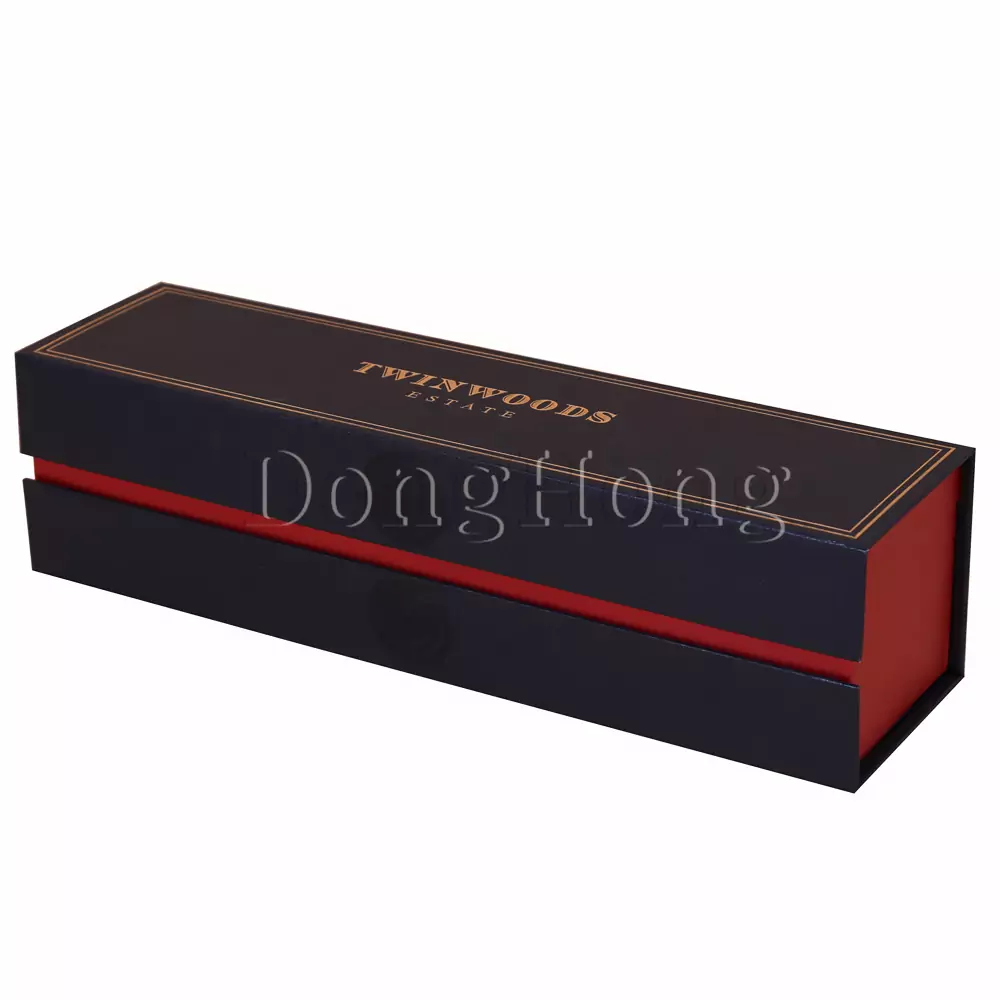

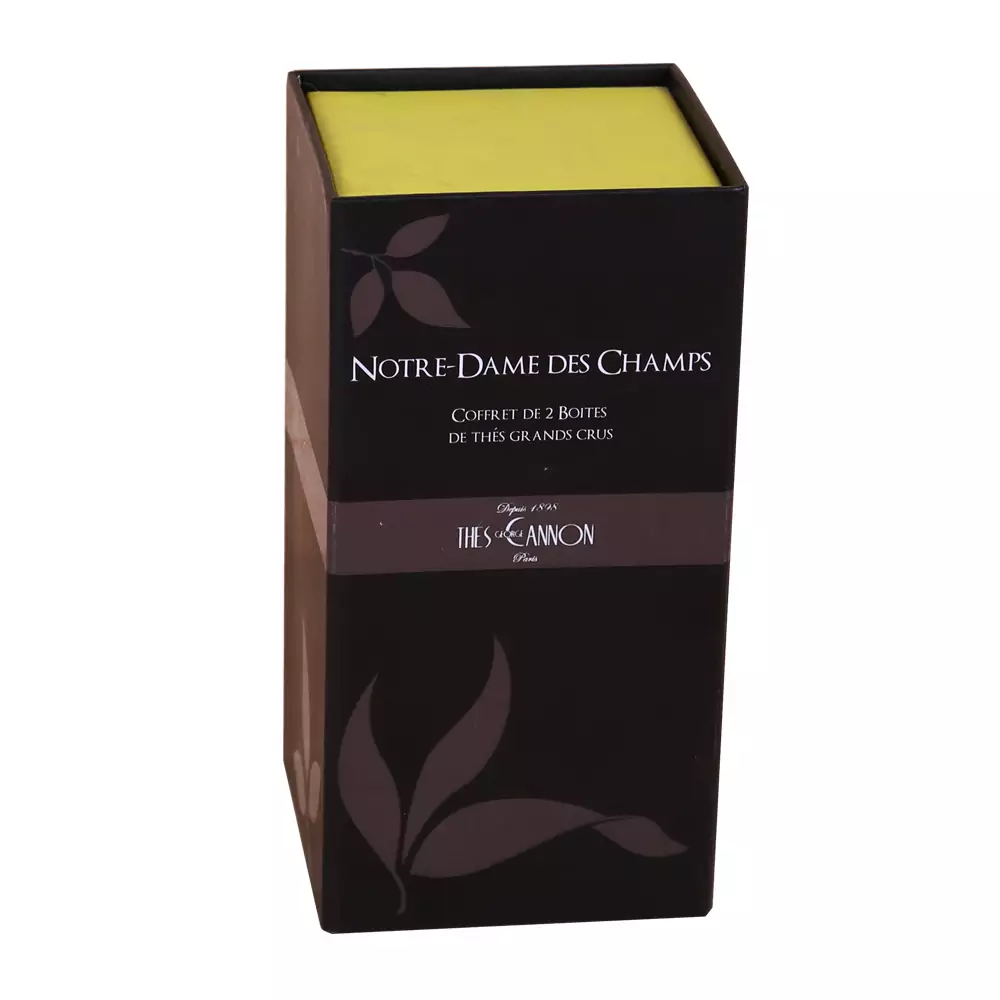

The physical size of the cigarette pack affects structural design, material strength, and user experience. Proper design ensures the product fits securely while maintaining structural integrity through the supply chain. This includes choices about folding style, reinforcement, and inner supports that protect the cigarettes during handling.

5. Choosing the Right Packaging Materials

Selecting the appropriate material for cigarette packs is crucial for durability and regulatory compliance. Many brands opt for high‑quality paperboard with precise printing and lamination options that protect the product and reinforce brand identity. For enhanced sustainability, eco‑friendly board options and recyclable inks are becoming popular in packaging.

6. Common Materials & Manufacturing Processes for Cigarette Packaging

High‑quality cigarette packaging is not just about aesthetics — the choice of materials and manufacturing processes directly affects product protection, shelf appeal, regulatory compliance, and sustainability. Below we explore commonly used materials and advanced packaging techniques in the cigarette box industry.

📐 Common Materials Used in Cigarette Packaging

Paperboard & Cardboard: The most widely used base material, offering excellent printability, structural support, and recyclability. Cardboard also protects cigarettes during transport and handling.

Kraft & Eco‑friendly Paper: Increasingly adopted for its sustainability, biodegradability, and consumer appeal. Kraft boards are strong yet lightweight, suitable for retail cartons and custom designs.

Liner Paper & Foil Barriers: Inner liners using aluminum or laminated paper improve moisture and oxygen barrier properties, protecting freshness and quality.

Coated & Gloss Paper: Coated surfaces allow high‑definition printing and glossy finishes, enhancing brand visibility and premium feel.

Tinplate (for Specialty Boxes): In premium or collectible cigarette tins, tinplate materials provide durability, sheen, and corrosion resistance. Techniques like embossing and UV printing are often used on these metal surfaces.

🔧 Key Manufacturing Processes

The typical production journey of a cigarette packaging box involves a series of interconnected steps, each designed to add functionality, durability, and aesthetic appeal:

Die‑cutting & Creasing: Flat sheets of paperboard are precisely cut and scored using dies to form box panels, fold lines, and locking tabs — the foundation of high‑quality packaging.

Folding & Gluing: After cutting and scoring, boxes are folded and glued into shape, using either automated folder‑gluer machines or manual assembly for small runs.

Printing & Decoration: Advanced printing methods — including flexography, offset, spot‑color, and UV — are used to apply brand graphics, warning labels, and product information.

Foil Stamping & Embossing: Hot foil stamping, embossing, and debossing add texture and metallic accents to elevate the premium look of cigarette boxes.

Quality Inspection: After assembly and printing, boxes undergo rigorous checks for dimensional accuracy, print quality, and structural consistency to ensure they meet industry standards.

By combining the right materials with precise manufacturing processes, cigarette packaging can achieve both functional protection and high shelf appeal, while aligning with regulatory requirements and sustainability goals.

7. How DHPFactory Supports Your Packaging Needs

At DHPFactory, we specialize in custom cigarette packaging designed to fit standard pack sizes and unique brand requirements. Our end-to-end service includes material selection, structural design, printing, and finishing. By choosing us, you gain a packaging partner who understands both functional and aesthetic elements critical to product success.

Explore our range of services:

8. Frequently Asked Questions

Q1: Are 20 cigarettes always required in a pack?

In many markets, 20 is the legal minimum, but some regions allow variation depending on regulation and market demand.

Q2: Do packaging dimensions vary by brand?

Yes, while the cigarette count may be consistent, dimensions can vary based on branding, materials, and protective design elements.

Q3: What are the most eco-friendly materials used in cigarette packaging?

Eco-friendly options include kraft paper, recycled cardboard, and biodegradable films, which align with sustainability goals while maintaining product integrity.

Q4: Can cigarette packaging be customized?

Yes, packaging can be fully customized in terms of size, color, design, and material to reflect the brand's identity and meet regulatory requirements.

Q5: What is foil stamping in cigarette packaging?

Foil stamping is a process where metallic foils are applied to packaging to create shiny, high-impact visual effects, typically for logos and design highlights.

Q6: Are there regulations governing cigarette packaging?

Yes, packaging must meet regulatory requirements regarding health warnings, labeling, and size restrictions, which vary by country.

Q7: What is the minimum order quantity for custom cigarette packaging?

Minimum order quantities (MOQs) vary depending on design complexity and material choice, but typically start at around 500 units.

Q8: How long does it take to produce custom cigarette packaging?

The production time typically ranges from 15 to 30 days, depending on the complexity of the design and order volume.

9. Conclusion & Next Steps

Cigarette pack sizes play a foundational role in product presentation, regulatory compliance, and user experience. Understanding these fundamentals allows brands to make informed packaging decisions that enhance both function and aesthetics. As a trusted supplier, DHPFactory can help you design and produce effective cigarette packaging solutions that align with industry norms and brand goals.

Ready to enhance your cigarette packaging? Visit our Contact Page or explore our Cigarette Packaging Options to get started with a custom quote today!