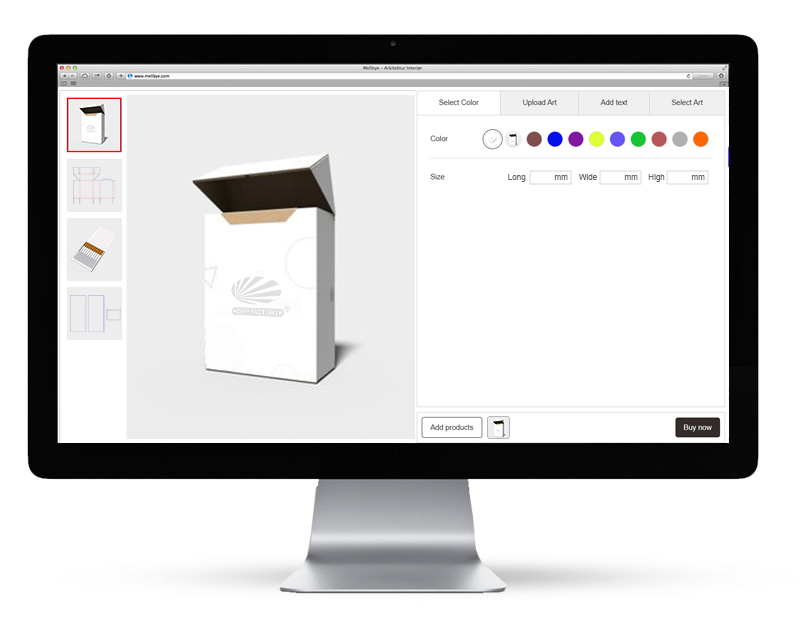

Exquisite, modern, and cleverly designed custom cigarette cases can showcase your brand's unique personality while protecting your cigarettes from damage.

Unique, brand-focused designs that stand out on shelves and in hands.

Wide range of color options to match your brand identity and appeal to your target audience.

Custom features like humidity control, child-resistant closures, and more.

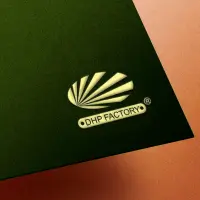

Hot stamping is a surface treatment process that involves engraving special hot stamping dye onto your design and heating it under high pressure to form a thin layer of gold foil.

Cold foil stamping is a high-tech process that leaves a matte finish on the surface of packaging boxes.

This dynamic surface treatment process cleverly uses light and shadow to give products a three-dimensional feel.

This processing technique does not use any ink or foil to emboss the pattern. It has a unique environmental consciousness.

Overprinting uses foil and ink to add creative 3D designs to product packaging. This process blends two different designs together to create a sense of depth and alignment within the texture.

This process combines hot stamping and embossing techniques to create a three-dimensional texture with a metallic sheen on the image. This surface treatment is ideal for brand lettering and logos, enhancing the overall look of the product.

UV coating is a transparent coating technique that is applied to different printing materials to attain shiny and glossy effect.

It is a high-end, glossy and UV-curved coating technique that prints specific surfaces of the material rather than whole material.

This process includes the application of a liquid coating to attain a velvety and soft-touch surface over the material.

Lamination is the process of connecting multiple layers with the key purpose of adding durability and protection to the product packaging.

Anti-scratch lamination provides a brushy and anti-scratch surface to the packaging. Hence, providing a luxury touch with cost-effective benefits.

Silk lamination is a smooth and protective lamination that adds a soft, subtle and silk-like touch to the packaging of the product.

Premium-grade bleached whitepaperboard coated on two sides for high-quality printing and finishes.

Black dyed kraft paper made from a mix of virgin and recycled pulp, coated on both sides for printing.

Specialty paper material featuring a glossy or matte metallic laminated surface.

Kraft paper made from a mix of virgin and recycled paper pulp, coated on both sides for printing.

Unbleached kraft paper with no coating. Made from a mixture of virgin and recycled paper pulp.

Premium-grade textured paper stock primarily used for wrapping rigid boxes.

Cardboard is famous for its stout and transparent nature. It is made of paper pulp and is commonly used for the packaging of multiple product boxes.

Kraft paper is one of the stout packaging materials. It is made from wood pulp and is famously adopted for its durability and reliability.

Rigid materials show high resistance during any stress and uphold the original shape of the product. Its stiffness and inflexibility make it suitable for many brands.

Corrugated material is made from cellulose fibre. This offers durable, reliable and cost-effective packaging solutions. It is also sustainable and recyclable making it one preferable material choice.

Cardstock is a thin and flexible paperboard which is widely used in scrapbooks, business cards, postcards and greeting cards and provides durable packaging results.

Bux board is primarily made of corrugated material with single, double and three layers making it tear-free and an ideal packaging material.

High-quality printing method that utilizes a printing plate and rubber blanket to transfer designs on paper. Best for large runs.

Digital printing method that requires no printing plate. Designs are transferred electronically, making it cost-effective for small runs.

Fast-drying printing method using ultraviolet lights to cure inks which results in a gloss finish.

Comprised of water and pigment that provides high-quality color output and is 100% eco friendly.

100% eco friendly and comprised of soy/vegetable oil and pigment to provide a vibrant color output.

Pure color based on specific ink formulas to consistently and precisely print color.

Contact DHPFactory solution experts for assistance.

We have a professional technical team to produce drawings for you and meet all your needs from prototype design to production.

Samples Available NowWe check and confirm sample specifications, dimensions and surface treatment requirements.

We will make a pre-production sample for final approval before mass production.

Confirm the product drawing.

We will provide you with quotation confirmation according to your product requirements.

You can confirm the product quality by samples order.

We select the most suitable manufacturer for your order, produce immediately and follow up the progress.

Through advanced testing equipment and professional quality personnel to ensure product quality.

Reliable cooperative logistics providers deliver goods on time and track them all the time.

We have a professional technical team to produce drawings for you and meet all your needs from prototype design to production.

Samples Available NowAll samples are secure and confidential.

We check and confirm sample specifications, dimensions and surface treatment requirements.

Confirm the product drawing.

We will provide you with quotation confirmation according to your product requirements.

You can confirm the product quality by samples order.

We select the most suitable manufacturer for your order, produce immediately and follow up the progress.

Through advanced testing equipment and professional quality personnel to ensure product quality.

Reliable cooperative logistics providers deliver goods on time and track them all the time.