Why Clothing Packaging Boxes Matter: The Secret to Higher Retail Value and Fewer Returns

For modern fashion and apparel brands, clothing packaging boxes are no longer “just a box”. The right structure, materials, and finishes can lift perceived retail value, protect garments in transit, and quietly reduce your return rate—all while telling your brand story.

Table of Contents

1. What Are Clothing Packaging Boxes and Why Do They Matter?

Clothing packaging boxes refer to custom-designed paper boxes used to protect, present, and ship garments such as shirts, yoga wear, hoodies, dresses, and premium fashion sets. A decade ago, many brands treated them as a simple container. Today, they are a strategic branding and operations tool.

From DHP Factory’s experience working with global apparel brands, three realities stand out:

First impressions are priced in. Customers subconsciously set a “price expectation” the moment they see and touch your box.

Most damage-related returns are preventable. Many arise from under-engineered or poorly sized apparel boxes.

Sustainability now affects buying decisions. Box material, recyclability, and perceived waste all influence brand preference.

As a manufacturer focused on luxury custom paper packaging, DHP Factory designs clothing packaging boxes not only to look on-brand, but to perform in transit, in-store, and in your customer’s hands.

2. How Apparel Boxes Increase Perceived Retail Value

Clothing packaging boxes directly influence how much a customer feels your product is worth—even when the garment itself has not changed. This perceived value translates into stronger pricing power, better reviews, and more repeat purchases.

A. First Impression & Shelf Price Expectation

A slim, rigid apparel box with clean edges, precise folding, and a soft-touch surface immediately signals “premium”. Customers expect higher quality garments and are more willing to accept a higher retail price.

Rigid or foldable magnetic clothing boxes feel substantial in hand.

Neat internal folding and tissue wrapping show care and attention.

Consistent brand colors and logo finishes create a unified identity.

B. Aligning Packaging Tier with Product Tier

Everyday basics, mid-tier collections, and luxury capsule lines should not share the same packaging level. When box quality and garment price mismatch, customers either feel overcharged or underwhelmed.

Everyday wear: eco-friendly foldable boxes with simple CMYK printing.

Premium lines: rigid or foldable magnetic boxes with foil, embossing, and special coatings.

Limited editions: unique structures or textured papers to create collectability.

C. Storytelling & Sustainability as Value Multipliers

Today’s fashion consumers look beyond logo and color. They care where materials come from, whether packaging is recyclable, and whether unboxing feels thoughtful rather than wasteful. By choosing the right paper, inserts, and finishes, your clothing packaging boxes can communicate:

Sustainability: recycled or FSC-style paper stocks, minimal plastic, and clear disposal cues.

Brand personality: calm neutrals for minimalist brands; bold graphics for streetwear; soft palettes for kids’ apparel.

Care for garments: inserts or dividers that keep items in perfect shape until they are worn.

On DHP Factory’s options & materials page, apparel brands can combine different paper grades, coatings, and inserts to match both price point and sustainability targets.

3. How Better Packaging Helps You Reduce Returns

When apparel brands talk about returns, they often focus on size and fit. But packaging-related factors quietly contribute to a significant share of preventable returns—and negative reviews.

3.1 Preventing Damage in Transit

Crushed collars, distorted hat brims, deep creases in suits, and scratched buttons are often the result of boxes that are too thin, too loose, or structurally weak. Clothing packaging boxes designed for shipping should:

Use board grammage and construction appropriate for courier handling.

Include inserts, dividers, or trays when garments need shape support.

Minimize empty space to reduce movement and abrasion.

DHP Factory frequently pairs apparel boxes with custom inserts (EVA, sponge, cardboard dividers, or paper pulp) to keep garments or accessories fixed in place during transportation.

3.2 Maintaining a Clean, “As-Promised” Appearance

Customers today expect their online orders to arrive “photo-ready”. If garments arrive wrinkled, dusty, or loosely bundled, they are more likely to be perceived as used, cheap, or mishandled—even if the product itself is fine.

Boxes designed around folded garment dimensions help avoid over-compression.

Inner wrapping (tissue paper, kraft wrap, or dust bags) maintains a clean look.

Window or partial-open structures reassure customers about color and texture.

3.3 Reducing Post-Unboxing Regret

Well-designed clothing packaging boxes also act as storage. If the box is sturdy and attractive enough to keep, customers are less likely to feel they overpaid—and more likely to view the purchase as a long-term item rather than impulse clutter.

For example, foldable magnetic boxes and drawer-style apparel boxes from DHP Factory can double as wardrobe organizers, lingerie or T-shirt sorters, or accessories storage, increasing perceived lifetime value.

4. Key Clothing Packaging Box Styles and When to Use Each

Different apparel collections call for different box structures. Below are some of the most common clothing packaging box types used by DHP Factory’s fashion clients, and when each works best.

| Box Style | Best For | Benefits for Retail Value & Returns |

|---|---|---|

| Foldable Magnetic Clothing Box | T-shirts, hoodies, activewear, subscription sets | Ships flat to save freight and warehousing cost; sets up into a rigid-feel box with magnetic closure. Great for mid to high-tier apparel brands needing a balance of premium feel and logistics efficiency. |

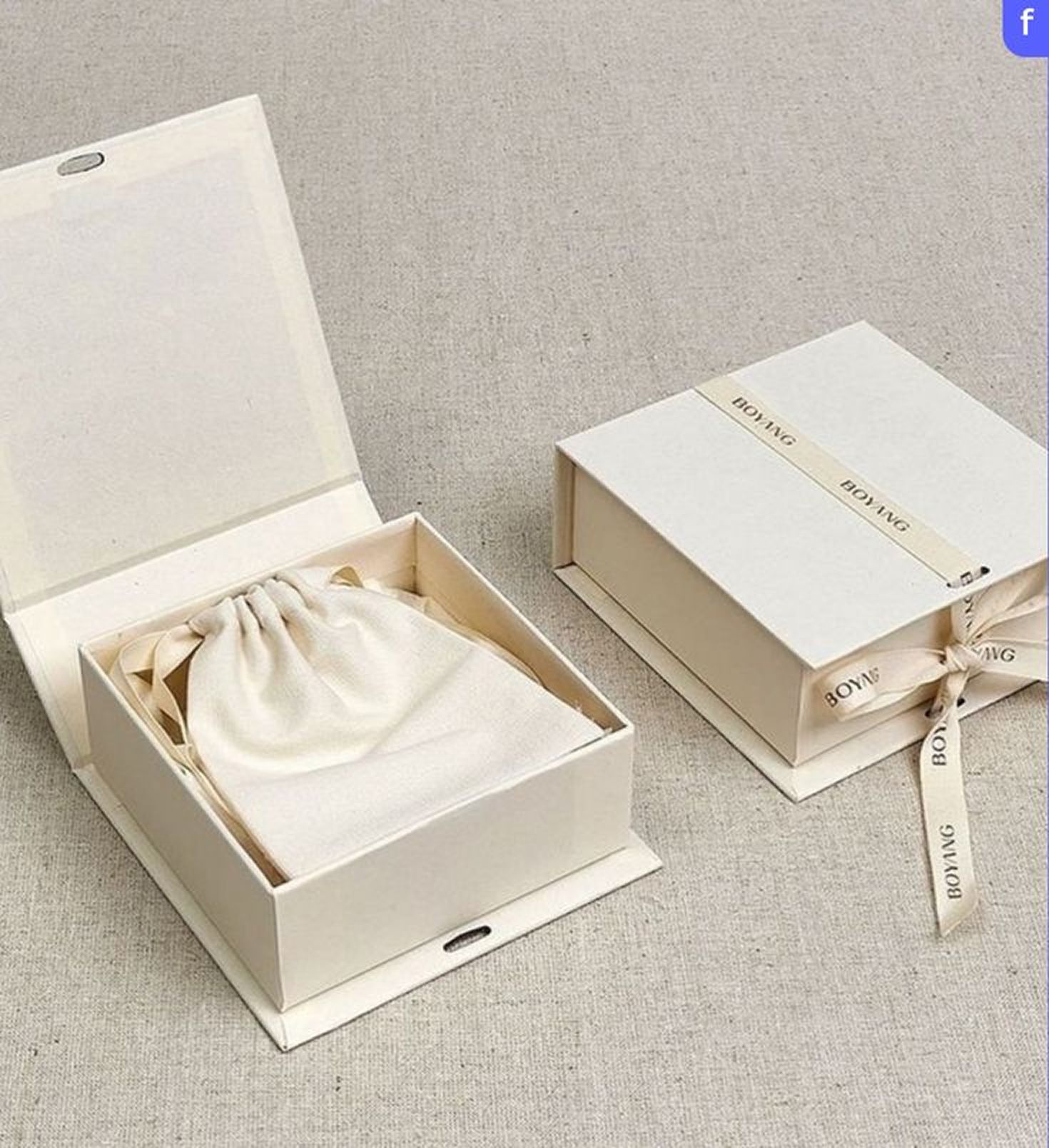

| Rigid Two-Piece Apparel Gift Box | Luxury shirts, knitwear, tailored garments, gifting sets | Heavier board and clean corners deliver a strong “gift-ready” impression. Excellent for in-store gifting and e-commerce orders where unboxing is part of the experience. |

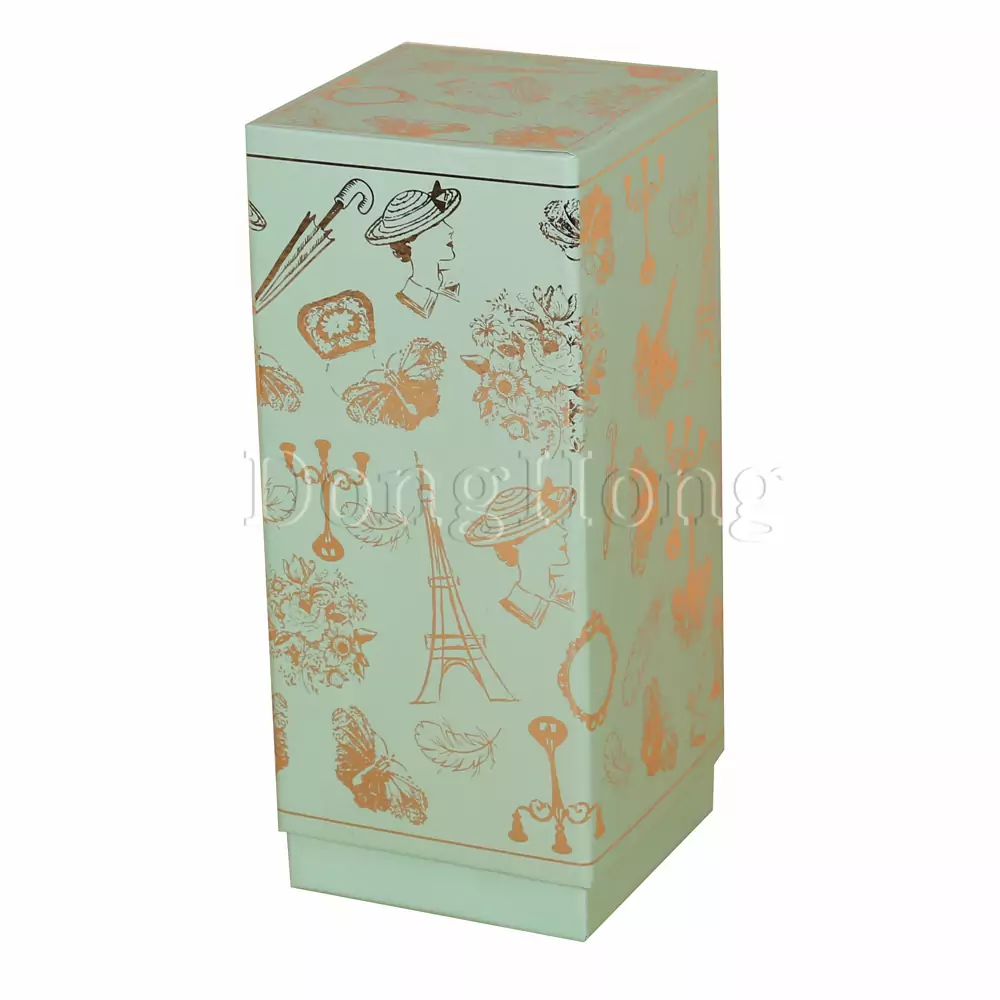

| Drawer / Sleeve Clothing Box | Lingerie, accessories, premium athleisure, matching sets | Drawer motion feels elegant and slows down the unboxing moment. Inserts keep items in place, reducing damage; outer sleeve gives extra printing area for storytelling. |

| Mailer Box for Clothing | Direct-to-consumer shipping, returns-ready packaging | Corrugated or reinforced paperboard optimized for shipping. Works well with printed interior and branding to balance cost, protection, and customer delight. |

| Special Occasion Clothing Gift Box | Wedding dresses, bridesmaid sets, seasonal collections | Larger rigid or foldable structures with ribbon handle or window, suitable for ceremonial garments. When properly engineered, they protect voluminous dresses while making them feel truly special. |

For more inspiration on garment-related structures, you can explore DHP Factory’s apparel and gift box solutions via the foldable boxes section and related clothing packaging items.

5. DHP Factory’s Recommended Structure & Finish Combinations

Beyond structure, the combination of materials and finishes you choose will determine how your clothing packaging boxes feel in hand—and how well they protect garments. Below are some DHP Factory–recommended pairings, together with example product links you can reference when briefing your project.

5.1 For Modern Fashion & Streetwear Brands

Recommended combo: Foldable magnetic apparel box + CMYK printing + matte lamination + spot UV logo + ribbon handle.

Why it works: Matte lamination gives a refined, non-reflective finish; spot UV on the logo adds a subtle “pop” without being overly flashy.

Best for: mid- to high-end T-shirt, hoodie, or yoga wear brands that want a premium feel but still need flat shipping.

Example DHP Factory product: Magnetic Collapsible Box with Ribbon Handle – a folding magnetic gift box with UV coating and matte lamination that can be adapted as a clothing packaging box with your logo and artwork.

5.2 For Bridal, Occasion Wear & Premium Dresses

Recommended combo: Rigid clothing gift box + art paper over greyboard + soft-touch coating or matte lamination + foil stamping on logo + wide satin ribbon closure.

Why it works: The soft-touch or matte surface feels velvety, while metallic foil stamping on your brand name reinforces “once-in-a-lifetime” value for bridal and eveningwear.

Best for: wedding dress brands, bridesmaid proposal sets, premium occasion wear.

Example DHP Factory product: Wholesale Decorative Ribbon Clothing Gift Wedding Dress Box – a rigid clothing gift box for dresses, produced with art paper and rigid cardboard, offered with customizable printing and finishes including gloss/matte coating, spot UV, and soft touch.

5.3 For Gift Sets, Loungewear & Accessories

Recommended combo: Foldable or rigid drawer-style box + leatherette or specialty paper + hot stamping + optional EVA or sponge insert.

Why it works: Drawer motion plus textured paper makes even simple loungewear or homewear sets feel like a considered gift. Inserts keep garments or accessories (scarves, belts, socks) neatly displayed.

Best for: curated gift sets, capsule collections, accessory bundles.

Example DHP Factory product: Customized Folding Paper Box with Ribbon Closure – a folding box made from leatherette paper and rigid board, with options for hot stamping, matte/gloss lamination, spot UV, and a range of inserts (EVA, sponge, velvet, cardboard).

5.4 For Eco-Minded Apparel Brands

Recommended combo: Foldable or mailer-style box + recycled or kraft-style paper + minimal inks + matte AQ or no lamination + paper or pulp inserts.

Why it works: Visibly sustainable materials and restrained printing clearly communicate your environmental values without compromising protection.

Best for: sustainable fashion labels, kids’ apparel, and basics where eco-credentials matter.

Where to start: DHP Factory often adapts its foldable gift and moving box structures for apparel, with an emphasis on reusable, eco-friendly designs. You can reference the related products group that includes clothing gift boxes and foldable organizers when briefing your eco apparel packaging project.

6. How to Work with DHP Factory on Custom Clothing Boxes

As a one-stop luxury packaging manufacturer, DHP Factory supports apparel brands from concept to delivery. Here is a simple roadmap to launching your next generation of clothing packaging boxes.

Share your brand and collection details. Describe your garments (category, sizes, fabrics), price point, sales channels (online/offline), and sustainability requirements. This helps us recommend a suitable structure and board thickness from the start.

Choose structure, materials, and finishes. Together we decide between rigid, foldable, drawer, or mailer structures, and select paperboard, coatings, and finishes using the options shown on the options & materials page .

Develop dielines and artwork. Our team provides or confirms dielines; your designers create artwork in AI/PDF/CDR format. If you need help, DHP Factory can advise on logo placement, color behavior, and print-friendly layouts.

Sample, test & refine. We produce samples for you to test with your actual garments—checking fit, stacking, and transit performance. Any adjustments to size, inserts, or finishes are made before mass production.

Mass production & logistics. Once confirmed, production starts under strict quality control. Boxes can be shipped flat (for foldable styles) or pre-assembled, depending on your warehouse and packing workflow.

You can learn more about DHP Factory’s background and capabilities via the About Us page, or speak directly with our team via the Contact Us form.

Ready to Upgrade Your Clothing Packaging Boxes?

Whether you’re scaling a DTC apparel brand or repositioning a fashion label at a higher price point, DHP Factory can help you engineer clothing packaging boxes that both delight customers and reduce preventable returns.

7. FAQ: Practical Questions from Apparel Brands

At minimum, we need your box dimensions (L × W × H), quantity, preferred structure (foldable magnetic, rigid, drawer, or mailer), basic artwork concept, and any special insert or finish requirements. Sharing garment photos and how you ship (flat or on hangers) also helps us optimize the design.

Yes. Based on your current damage scenarios, DHP Factory can recommend stronger board, different folds, or custom inserts (foam, sponge, or cardboard) that better support your garments in transit. Often, small adjustments in structure and size significantly reduce crushed collars, bent brims, or deep creases.

Most of our apparel boxes are made from recyclable paper-based materials, and we can propose eco-focused options such as recycled paperboard, kraft-style papers, minimal plastic, and water-based coatings. Let us know your sustainability goals and we will tailor material combinations accordingly.

In many cases, yes. During the structural design stage, we can help you define 2–3 “core sizes” that cover most of your SKUs (for example, tees, hoodies, and light jackets), using inserts or folding variations to keep garments stable inside the box. This reduces tooling complexity and inventory cost.

Lead time depends on structure complexity, finishing requirements, and order quantity. After artwork and samples are confirmed, mass production usually takes several weeks, plus shipping time to your warehouse. We recommend aligning packaging development with your collection calendar as early as possible.