Cigarette Brands: How to Build Brand Influence Through Customized Packaging

In the highly regulated and fiercely competitive tobacco and nicotine market, packaging has become one of the most powerful tools for brand differentiation. For cigarette brands, customized packaging is no longer just a container—it is a strategic asset that shapes perception, communicates compliance, and builds long-term brand influence at the point of sale.

Why Packaging Matters for Cigarette Brands

Cigarette packaging plays a unique role compared to other consumer products. With limited advertising channels and strict regulatory frameworks, the box itself often becomes the primary brand touchpoint. Color, structure, texture, and opening experience directly influence how a brand is perceived on retail shelves.

Well-designed cigarette packaging helps brands achieve three key objectives: instant recognition, trust through quality presentation, and differentiation in crowded retail environments.

The Competitive Advantage of Customized Cigarette Packaging

Standardized packaging may meet basic requirements, but customized cigarette boxes allow brands to control every visual and functional detail. From box dimensions to tactile finishes, customization enables a cohesive brand system that extends across product lines and markets.

Custom packaging also supports brand segmentation. Entry-level, mid-range, and premium cigarette products can be clearly differentiated through materials, finishes, and structural design—without changing the core brand identity.

Box Structures & Material Choices

Selecting the right structure and material is the foundation of effective cigarette packaging. Each option serves a different brand positioning and market need.

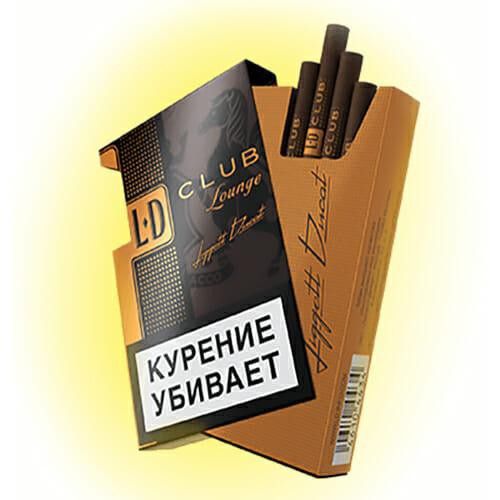

Folding Carton Boxes: Lightweight, cost-efficient, and ideal for high-volume production while maintaining print clarity and regulatory labeling.

Rigid Cigarette Boxes: Often used for premium or limited-edition lines, offering enhanced protection and a refined unboxing experience.

Drawer & Flip-Top Structures: Designed to improve usability and reinforce brand memorability through unique opening mechanisms.

At DHPFactory, material selection is guided by both branding goals and regulatory requirements, ensuring durability, consistency, and production efficiency.

Printing, Finishing & Brand Storytelling

Printing quality and finishing techniques are where brand influence truly comes to life. Beyond basic CMYK printing, premium cigarette brands increasingly rely on advanced finishing to communicate value and authenticity.

Hot foil stamping for logo emphasis

Embossing and debossing for tactile differentiation

Spot UV coatings to highlight brand elements

Soft-touch lamination for a refined hand-feel

When combined thoughtfully, these techniques allow cigarette packaging to tell a brand story—one that is felt as much as it is seen.

Compliance & Sustainability Considerations

Compliance is non-negotiable in cigarette packaging. Warning labels, barcode placement, and mandatory information must be integrated seamlessly without compromising brand design.

At the same time, sustainability has become a growing concern for both regulators and consumers. Recyclable paperboard, FSC-certified materials, and environmentally responsible inks are now key decision factors for global cigarette brands.

DHPFactory supports eco-conscious packaging strategies while maintaining strict quality control and regulatory accuracy for international markets.

Choosing the Right Manufacturing Partner

The success of customized cigarette packaging depends heavily on manufacturing expertise. Brands must work with suppliers who understand precision printing, structural consistency, and scalable production.

Key evaluation factors include production capacity, quality systems, material sourcing, and the ability to manage complex customization without compromising lead times.

Why Leading Brands Work with DHPFactory

As an experienced custom packaging manufacturer, DHPFactory provides end-to-end solutions for cigarette brands—from structural engineering and material selection to mass production and quality assurance.

Our team supports brands at every stage, helping translate design concepts into reliable, production-ready packaging that strengthens brand influence across global markets.

Learn more about our capabilities by exploring related solutions on our manufacturing overview or browsing our custom rigid and folding box offerings.

Start Your Custom Packaging Project

Customized cigarette packaging is a long-term brand investment. With the right structure, materials, and manufacturing partner, packaging becomes a powerful driver of recognition and loyalty.

If you are planning to upgrade or launch customized cigarette packaging, contact DHPFactory to discuss your requirements and request a tailored solution.