Most packaging problems don’t come from creativity—they come from missing specs, unclear compliance space, weak tolerance control, and sampling that doesn’t predict mass production.

This guide shows B2B buyers how to build a cigarette box that is quote-ready, compliance-aware, and production-stable.

If you’re sourcing custom cigarette box packaging, the goal is not only “premium-looking.” The goal is retail-ready performance: correct fit, consistent finishing, scuff-resistant packing, and predictable lead time.

Below is a practical blueprint used by professional buyers to avoid the most expensive mistakes.

1) Start with Positioning

Positioning determines your optimal structure, paper grade, finishing scope, and the tolerance level required to keep mass production stable. Buyers who start with artwork often end up redesigning once compliance zones and production feasibility are reviewed.

2) Lock the Structure

Structure drives user experience, protection level, assembly time, and defect risk. Choose based on how the pack will be used and shipped—not only how it looks on a render.

Flip-Top (Hinged Lid)

Scalable and familiar in retail

Strong cost-to-performance ratio

Lower defect risk for first launches

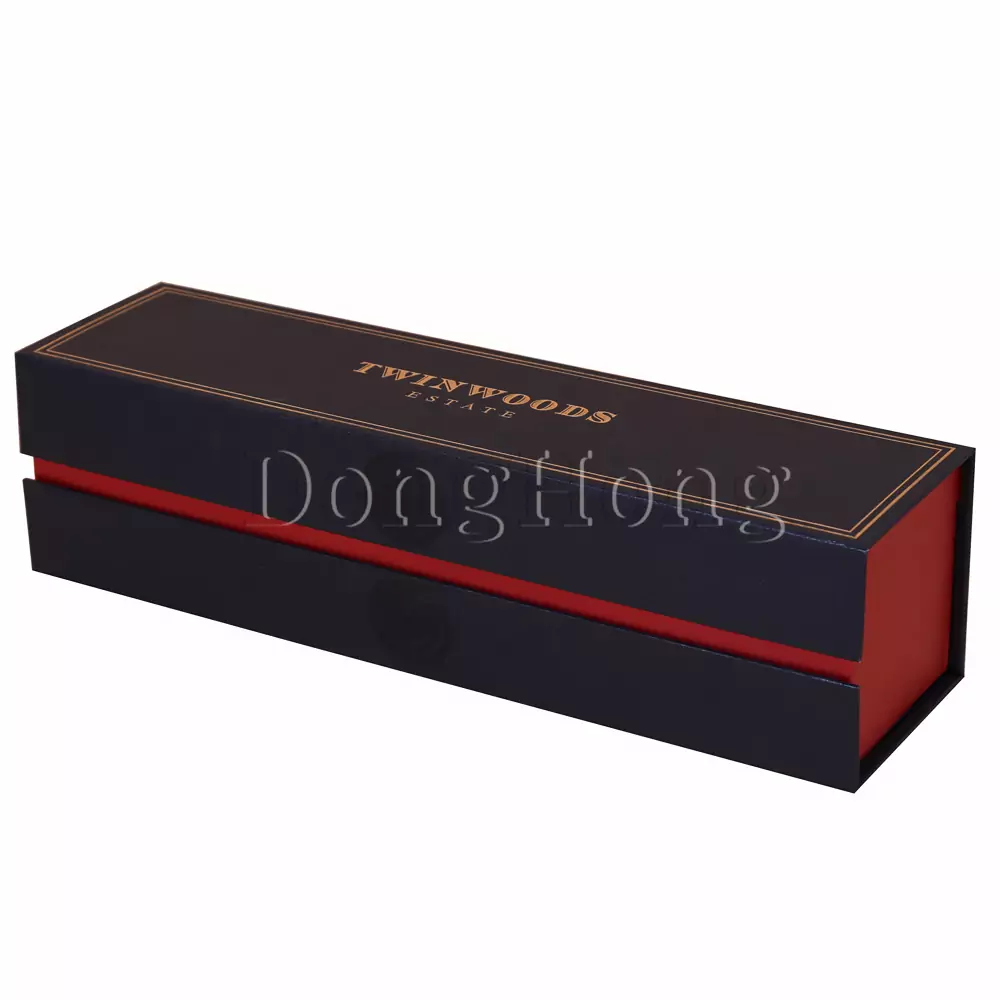

Drawer / Slide Box

Premium unboxing experience

Tighter tolerance required

More QC attention on friction & alignment

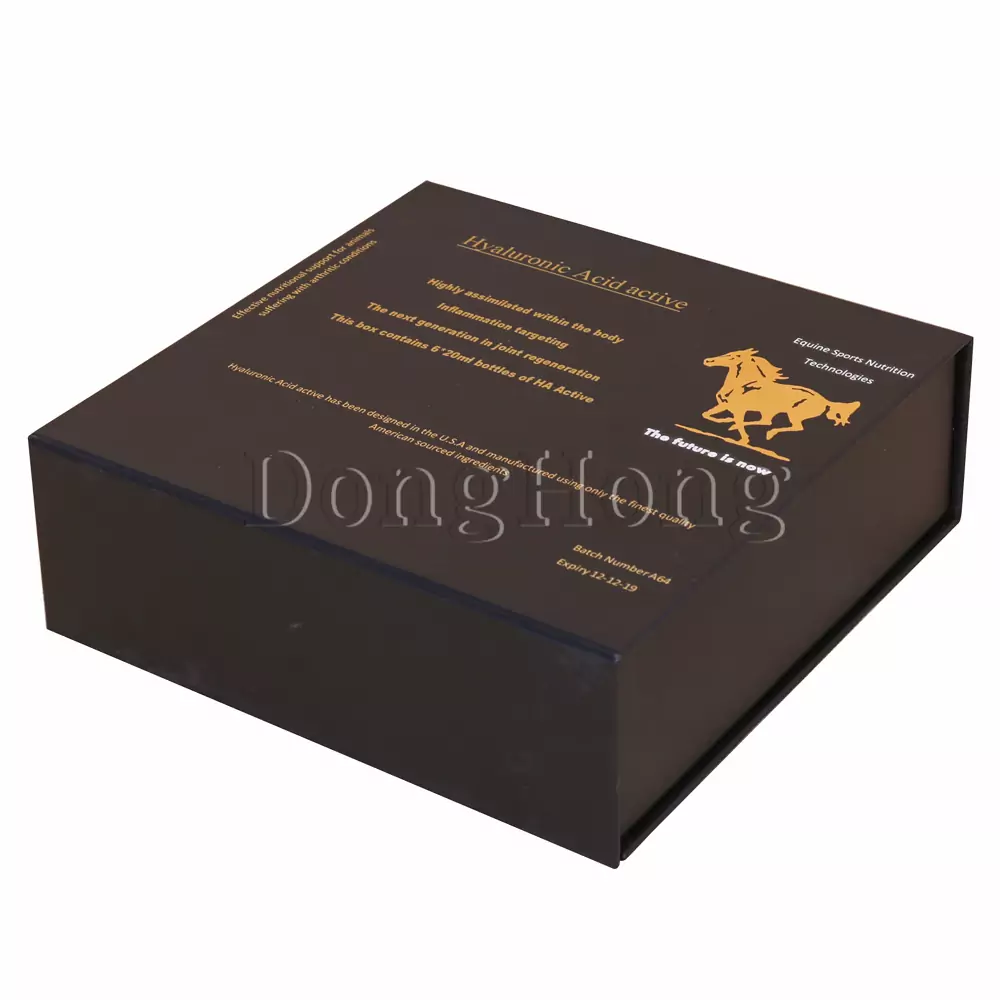

Magnetic Closure

Highest perceived value for gifting

Higher material + assembly cost

Strict finish protection needed in packing

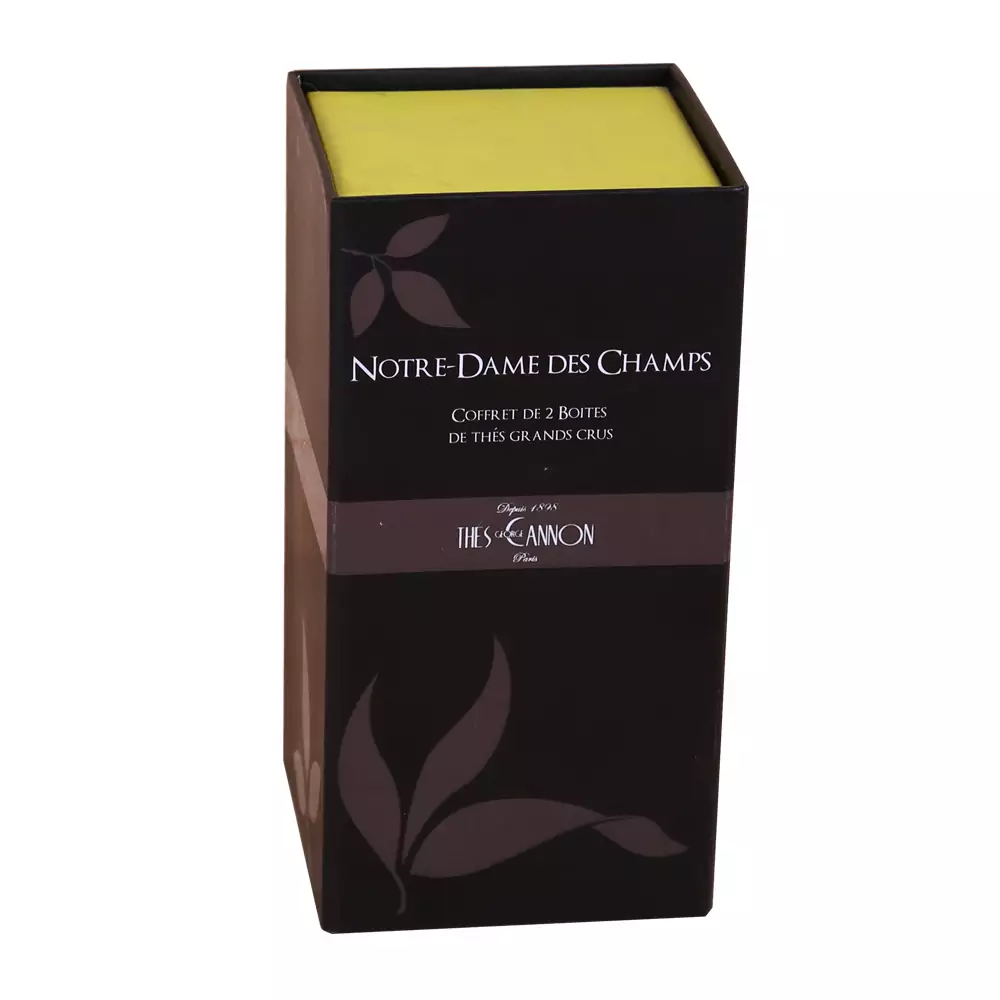

Soft Pack + Sleeve

Classic shelf style for certain markets

Fit control is critical (slide friction)

Strong storytelling potential with paper texture

3) Engineering Dimensions

“Almost correct” dimensions create movement, deformation, hard opening, and production rejects. Professional sizing starts from the real product, not a template.

Inputs needed for correct sizing

Stick length + diameter

Filter length

Sticks per pack + stacking layout

Inner wrap thickness

Humidity tolerance (minor expansion)

Opening feel target (tight vs smooth)

Barcode/trace placement needs

Retail tray compatibility (optional)

4) Materials

Paper choices affect premium feel, scratch resistance, fold cracking risk, and color stability. For cigarette packaging, material selection should align with handling intensity and shipping route.

5) Print & Finishes

Finishes create premium perception, but they also introduce defect variables. Professional buyers plan finishes with risk control: limited scope, stable adhesion, and strong surface protection.

High-Impact Options

Foil stamping (metallic / holographic)

Emboss / deboss (tactile signature)

Spot UV (controlled highlight)

Matte / soft-touch lamination

Low-Risk Premium Formula

One hero finish (foil OR emboss)

Keep negative space for a luxury feel

Limit foil area to reduce cracking risk

Use anti-scuff surface protection

6) Compliance Space Planning

Markets may require warning text/images, placement rules, and restrictions on claims. These requirements can reshape your design grid. Plan legal space early to avoid last-minute re-layout.

Compliance workflow used by professional buyers

Confirm target market(s) before final artwork

Reserve compliance zones in the dieline grid

Keep brand balance—don’t “design then patch”

Approve a compliance-ready proof before print

7) Sampling That Predicts Mass Production

Sampling is where buyers protect budget and timeline. A sample should verify the exact risk points that typically fail in mass production: alignment, adhesion, scuff resistance, and opening performance.

8) QC & Packing Standards

Quality control is not only inspection—it's agreement on acceptance standards. Premium cigarette packaging often fails not in production, but in packing and transit scuffing.

Key acceptance points (buyer checklist)

Dimension tolerance consistency

Opening performance (smoothness, resistance)

Corner alignment & edge crispness

Color tolerance control

Foil/UV adhesion (no cracking/flaking)

Emboss registration consistency

Anti-scuff packing method

Carton strength for shipping stability

9) Cost & Lead Time Drivers

Quotes become fast and accurate when structure, dimensions, materials, finishes, and quantity are locked. Most cost increases come from complex structures, large foil areas, specialty papers, and repeated revisions.

Top cost drivers

Structure complexity (drawer/magnet > flip-top)

Material grade (specialty paper, thicker board)

Finishing scope (foil area, multi-step processes)

Order quantity (unit cost decreases with volume)

Packing protection (anti-scuff methods)

Revision cycles (compliance/layout changes)

Typical timeline

Sampling: often 5–10 working days

Mass production: commonly 20–35 working days

Shipping: varies by destination & method

RFQ Checklist: Send This for Accurate Pricing

Box structure (or reference photo)

Cigarette format + sticks per pack

Target dimensions or cigarette sample details

Target market(s) for compliance planning

Material preference (standard vs premium)

Finishes (foil/UV/emboss/lamination)

Quantity + delivery deadline

Artwork status (ready / in progress / need support)

Packing requirements (anti-scuff, carton specs)

Anti-counterfeit needs (optional)

FAQ: Custom Cigarette Box Packaging

What’s the safest structure for a first launch?

How do I prevent fit issues?

Which finishes look premium with lower defect risk?

What should I approve during sampling?

What information gives the fastest and most accurate quote?

Need a Production-Ready Cigarette Box Spec?

Send your format, target market, positioning, and quantity. DHPFactory will recommend a packaging direction (structure + sizing approach + materials + finishes + sampling roadmap) aligned to your risk and timeline.