Updated: December 30, 2025 • Practical packing guide for brands, eCommerce sellers, and fulfillment teams

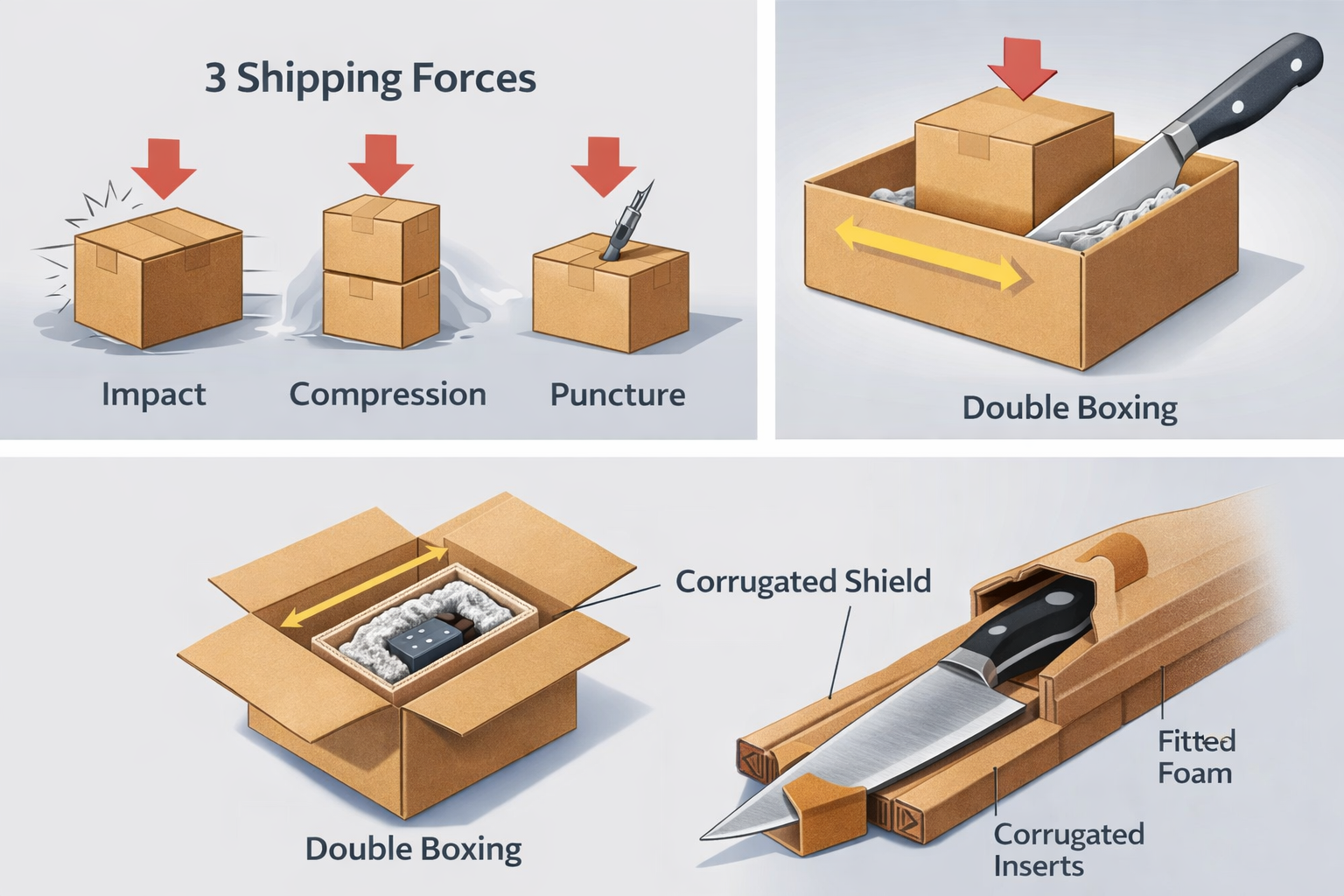

Shipping damage usually comes from three things: impact (drops), compression (stacking), and puncture (sharp edges). This guide shows how to control all three—using the right outer carton, smart cushioning, secure immobilization, and edge protection—so your products arrive safe and presentable.

Fast checklist (2 minutes)

Immobilize: the product should not shift when you gently shake the box.

Protect edges: sharp tips must be capped, wrapped, and taped so they cannot pierce packaging.

Keep a buffer zone: maintain cushioning between product and box walls on all sides.

Right-size the shipper: avoid oversized cartons that invite collapse and movement.

Seal correctly: use a reinforced “H” seal on the top and bottom seams.

Double-box for high risk: fragile + valuable + long-distance usually needs an inner pack and an outer shipper.

Test one unit: shake, corner press, and a short controlled drop test before scaling production.

Assess risk: fragile vs. sharp vs. both

Before you choose any box or insert, classify your product. Your packing method should match the failure mode:

| Item type | Main risk | Primary control | Typical upgrade |

|---|---|---|---|

| Fragile (glass, ceramics, electronics) | Impact + vibration | Cushioning + immobilization | Double-boxing |

| Sharp (blades, tools, metal parts) | Puncture + abrasion | Edge caps + rigid shields | Reinforced corrugated + partitions |

| Fragile + sharp (glass with sharp edges, precision components) | All three | Edge protection + cushioning + immobilization | Custom insert + double-boxing |

If you’re shipping regulated hazardous goods, follow the relevant regulations and carrier requirements. This article focuses on common consumer and commercial products.

Choose the right materials (carton + insert)

Safe shipping is a system: outer shipper (strength) + inner protection (cushioning & positioning). For premium unboxing, you can use a rigid gift box, but for transit you still need a properly engineered shipper or master carton.

Outer shipping carton: strength and sizing

Right size: leave space for cushioning, but not so much that items can “run” inside the box.

Stronger when heavier: as weight increases, upgrade the shipper grade and consider double-wall corrugated.

Reinforce corners: corners take the first hit during drops and conveyor transfers.

Inner protection: inserts that control movement

Inserts are often the difference between “arrived broken” and “arrived perfect.” For a quick overview of insert types and what they do, explore DHPFactory’s Insert Options.

For fragile: choose inserts that suspend or cradle the item (foam, molded pulp, structured paper tray).

For sharp: add rigid shields (corrugated pads, paperboard sleeves) plus edge caps to prevent puncture.

For sets: use dividers or partitions so items never touch each other during vibration.

Step-by-step: packing fragile items

1) Wrap the product like it will be dropped

Fragile items fail at contact points. Wrap the product to create a continuous cushion layer, then add extra protection on corners, edges, and protruding parts.

Use cushioning that can absorb impact without “bottoming out.”

Focus extra layers on corners and high-stress points (necks, handles, sharp transitions).

Keep the wrap tight so it doesn’t loosen during vibration.

2) Immobilize inside the inner pack

Your goal is simple: the item should stay centered and not touch box walls. Inserts, partitions, or a fitted tray make this far easier than loose fill alone.

3) Add a buffer zone to every side

Leave protective space on all sides (including the top and bottom). If the product is too close to the carton wall, a single corner drop can transmit force directly into the product.

4) Double-box when the risk is high

For fragile, high-value, or long-distance shipments, use an inner pack (product + insert) and place it inside an outer shipper with additional cushioning between the two. This dramatically improves impact resistance and reduces cosmetic damage.

Simple in-house tests before shipping

You don’t need a lab to catch most problems. Test one packed unit before you scale:

Shake test: gently shake; if you hear movement, improve immobilization.

Corner press: press corners and top panel; if the carton flexes easily, upgrade shipper strength or reduce void space.

Controlled drop: a short drop on a corner and an edge (within your internal policy) can reveal weak points fast.

Unbox inspection: check not only breakage, but scuffs, dents, and finish damage.

If your product is premium, test for “presentation damage.” A box that arrives intact but scuffed can still trigger returns.

Safer and more sustainable protection

Sustainable packaging can be protective when it’s designed correctly. Paper-based structures, molded pulp, and engineered paper inserts often outperform loose fill because they control movement.

Molded pulp trays: excellent for cradling and repeatable positioning.

Corrugated partitions: ideal for multi-item sets and bottle separation.

Paperboard sleeves and shields: useful for puncture resistance around sharp components.

If you want to compare options quickly, see DHPFactory’s Paper Options and Insert Options.

How DHPFactory helps you ship safely

DHPFactory is a one-stop custom packaging manufacturer supporting brands that need both protection and premium presentation. If you ship fragile or sharp items, we can help you select a safer structure, engineer inserts to stop movement, and match finishes that protect your brand image.

Box structures: choose styles that fit your product and workflow via Structure Options.

Insert engineering: molded pulp, corrugated, paper card, dividers, EVA, and more via Insert Options.

Surface protection: coatings and finishing that improve scuff resistance via Surface Finishes.

Accessories: handles, windows, locks, and tapes via Accessories Options.

For inspiration, browse popular categories like Rigid Boxes and Liquor & Wine Boxes—then we’ll adapt the structure and insert to your shipping scenario.

If your procurement requires compliance documentation, you can review DHPFactory certificates and audits on our Our Certificates page.

FAQ

Is “Fragile” labeling enough to prevent damage?

When should I double-box?

What’s the biggest mistake when packing sharp items?

How do I stop items from moving inside the box?

Can premium rigid boxes be used for shipping?

How do I choose the right insert material?

How much empty space should I leave in a shipping carton?

Can you help create a packing SOP for my fulfillment team?

Need a safer packaging solution for your product?

Send your product details (size, weight, fragile/sharp points, target market, and estimated quantity). DHPFactory can recommend a structure and insert system designed to reduce breakage, puncture, and presentation damage.